Why Did My 5V DC UV Intensity Sensor Burn Out? How to Protect It Properly

Common Causes of Sensor Burnout

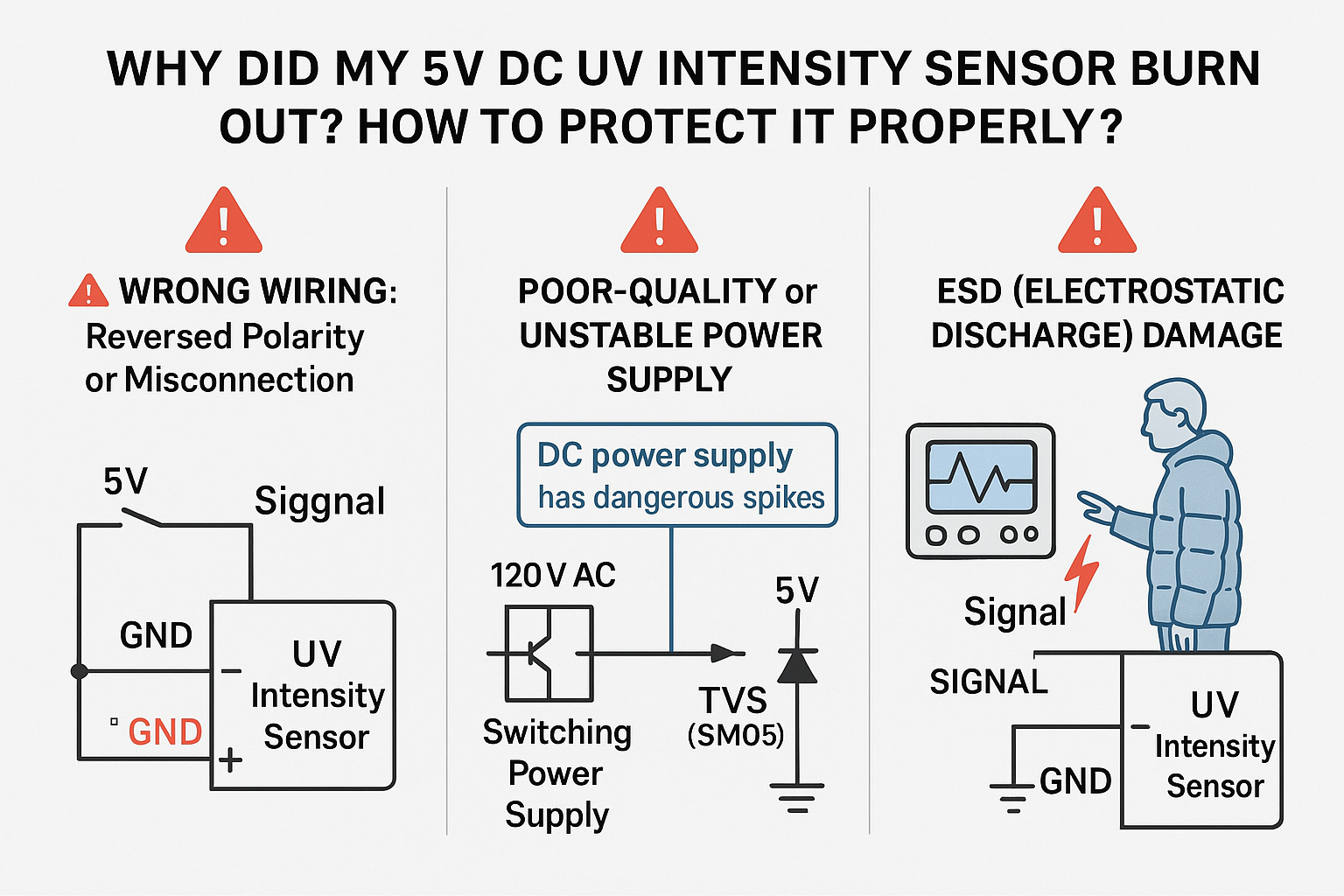

Many customers have experienced unexpected burnout of their 5V UV intensity sensors. Based on engineering analysis, the following are the three most common reasons:

❌ 1. Incorrect Wiring

If the power supply lines are connected in the wrong order—such as reversing +5V and GND, or mistakenly connecting the signal output line to the +5V supply—the internal chip may be permanently damaged.

🛠 Prevention Tips:

-

Always follow the wiring diagram in the user manual.

-

Use color-coded cables and labels.

-

Double-check connections before powering on.

⚡ 2. Unstable or Noisy Power Supply

Some users build their own 5V DC power using low-cost switch-mode power supplies (e.g. 90–265V to 5V) or step-down transformers, which may not have good voltage regulation or filtering. If the voltage briefly spikes above 5.5V, the UV sensor’s chip can be destroyed.

🧪 How to Check for Spikes Using an Oscilloscope

To ensure your 5V DC power supply is safe:

-

Use a digital oscilloscope to monitor the output voltage.

-

Watch for any high-frequency noise, voltage spikes, or transients exceeding 5.5V.

-

Even short pulses can damage sensitive electronics.

🛠 Recommended Fixes:

-

Use a high-quality power supply with EMC filtering.

-

Add filter capacitors (e.g. 100µF + 0.1µF) near the sensor.

-

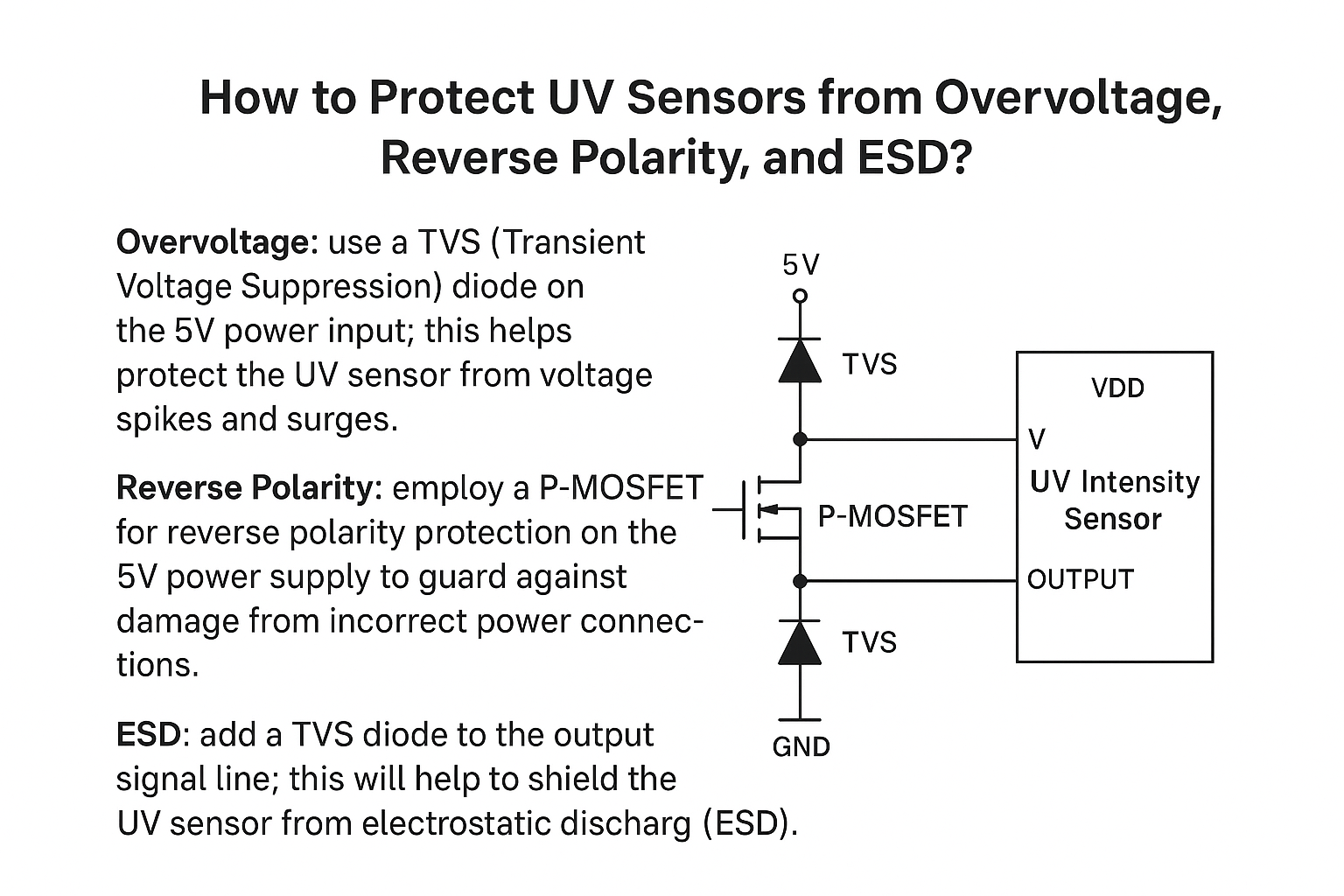

Install a TVS diode (e.g. 5.0V) between +5V and GND to clamp dangerous spikes.

⚠️ Note: Adding too many protection components may cause a voltage drop, especially if you are drawing current through a long cable or shared power rail. This drop (e.g., 0.2–0.3V) may cause your sensor to output a slightly lower signal than expected. Please account for this in your circuit design.

⚡ 3. Electrostatic Discharge (ESD) from Human Touch

If the device is not properly grounded, static electricity from operators (especially in winter, when wearing wool sweaters or down jackets) can discharge into the sensor. A typical human ESD event can exceed 6,000V, which easily destroys CMOS-based sensor chips.

🛠 Prevention Tips:

-

Ensure the equipment is properly grounded.

-

Use anti-static gloves or wrist straps during installation.

-

Avoid touching the sensor’s signal line with bare hands.

✅ Summary: Best Practices to Protect Your UV Intensity Sensor

| Problem | Cause Example | Protection Tip |

|---|---|---|

| Incorrect Wiring | Reversed +5V and GND | Label wires, check connections carefully |

| Unstable Power Supply | Poor-quality switch-mode PSU | Use oscilloscope, add capacitors, TVS diodes |

| Electrostatic Discharge (ESD) | Static from human body | Ground system, use ESD safety measures |

If you need help selecting power supplies or protection circuits for your UV sensors, feel free to contact our technical team. We’re here to help.

Leave A Comment