How to Use Tools to Measure UV Sensor Screw Type and Size | G Thread vs NPT Explained

1. Why do I need to know the screw type and size of my UV sensor?

Knowing the correct screw type and size ensures that your UV sensor can be safely connected to fittings, flow cells, or sampling systems. Using the wrong thread (for example, G instead of NPT) can lead to leakage, poor sealing, or damage.

2. What tools do I need to measure the screw thread of a UV sensor?

You will need three basic measuring tools:

-

Vernier Caliper – to measure the outer diameter (OD).

-

Thread Pitch Gauge – to measure the thread pitch (distance between threads) or TPI (threads per inch).

-

Thread Angle Gauge or magnifier – to identify the thread angle (55° for G thread, 60° for NPT thread).

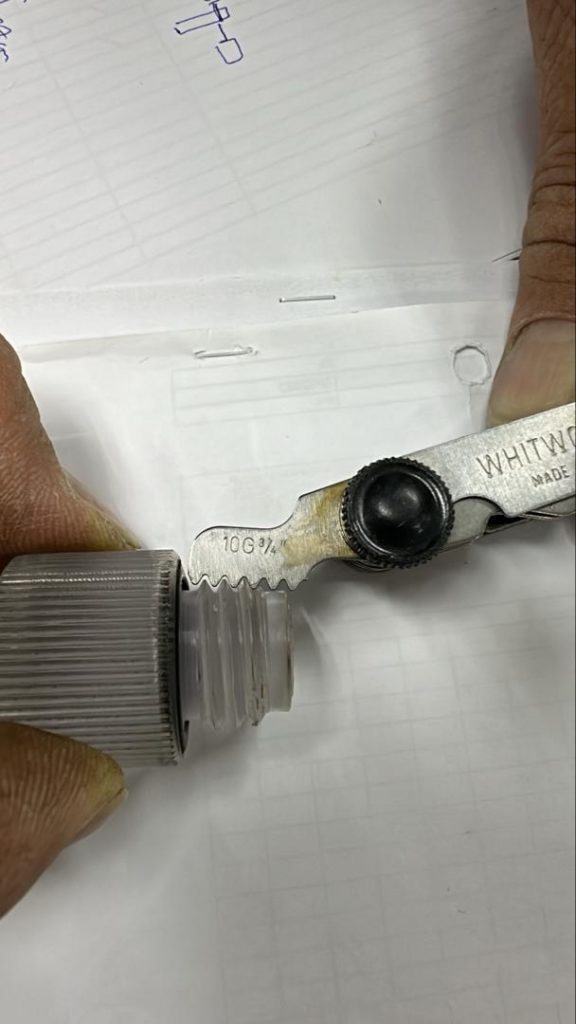

APOSUN-UV-sensor-screw-type-measuring-tool-Measuring-Tools-–-Thread-Gauge |

APOSUN-UV-sensor-screw-size-measuring-tool-Measuring-Tools-–-Caliper |

3. How to understand thread geometry before measuring?

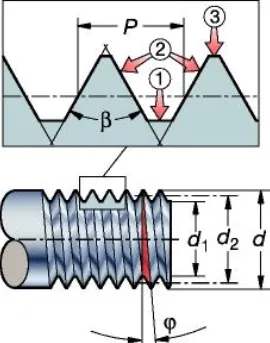

The diagram below shows the key thread parameters used for identification.

APOSUN-UV-sensor-screw-thread-Geometry-Illustration

In this diagram:

-

P (Pitch) – distance between two adjacent threads.

-

β (Thread Angle) – angle between the two flanks of the thread.

-

d (Major Diameter) – the largest diameter measured at the crest of the thread.

-

d₂ (Pitch Diameter) – the effective diameter where thread contact occurs.

-

d₁ (Minor Diameter) – the smallest diameter measured at the root of the thread.

These values are used to determine the thread size and standard (e.g., G 1/2″ or NPT 1/2″).

4. How to measure the screw size of a UV sensor?

-

Use the caliper to measure the outer diameter (OD) of the male thread.

-

Use a thread gauge to determine the pitch or TPI.

-

Compare your data with standard reference tables for G and NPT threads.

Example:

-

If the measured OD ≈ 20.9 mm and the pitch = 14 TPI, it could be either G 1/2″ or NPT 1/2″.

The next step is to check whether it’s parallel (G) or tapered (NPT).

5. How to distinguish between G and NPT thread types?

| Feature | G Thread (BSPP) | NPT Thread |

|---|---|---|

| Standard | ISO 228 / BSPP | ANSI / ASME B1.20.1 |

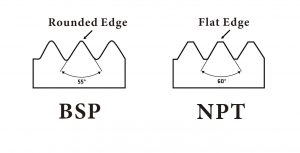

| Thread Angle | 55° | 60° |

| Taper | Parallel (no taper) | Tapered (1:16) |

| Sealing Method | O-ring or gasket | Thread sealant (PTFE tape) |

| Outer Diameter | Constant | Slightly decreasing along the thread |

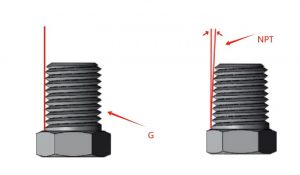

APOSUN-UV-sensor-G-and-NPT-different |

APOSUN_NPT-vs-BSP-Threads |

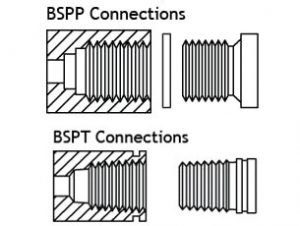

APOSUN_BSPP-BSPT-thread-connection |

You can easily identify the difference by checking if the thread gets narrower toward the end (NPT) or stays parallel (G thread).

6. Example: How to confirm if my UV sensor is G 1/2″ or NPT 1/2″?

-

Measure OD → around 20.9 mm.

-

Check pitch → 14 TPI.

-

Observe the thread shape:

-

Constant diameter → G 1/2″ (parallel).

-

Tapered → NPT 1/2″ (tapered).

-

-

Confirm the thread angle:

-

55° = G thread.

-

60° = NPT thread.

-

7. What happens if I use the wrong thread type?

Mixing G and NPT threads can result in:

-

Poor sealing or fluid leakage.

-

Thread damage due to forced tightening.

-

Inaccurate UV readings caused by air gaps or misalignment.

Always verify the thread type before connecting your UV sensor.

8. Can I send photos to confirm my UV sensor thread type?

Yes! You can send us:

-

A clear photo of the sensor’s threaded part.

-

A ruler or caliper next to the thread for reference.

Our team will help identify the correct thread type and size for your UV sensor fitting.Please contact sale@aposunmeter.com

Leave A Comment